Introduction

Just imagine when a car is in moving condition with a speed of about 70 mph, If we suddenly apply brake for an emergency situation, the brake immediately restricts the movement of the wheels which cause the skidding of wheel to some distance on the road, brake damage, wheel locking, and so the car losses its control from the driver that will lead to an accident. The ABS is used to avoid such kind of situation. ABS enables the driver to have steering control, prevents skidding and loss of traction. So we need ABS to maintain the directional control of the vehicle during heavy braking.Anti-lock braking system (ABS) is a feedback control system that monitors and controls the wheel slip during vehicle braking by providing modulated brake pressure in response to measured wheel deceleration. So, ABS can improve the vehicle's control during braking, and reduces stopping distance on the normal or slippery road surfaces by limiting wheel slip and minimizing wheel lockup.

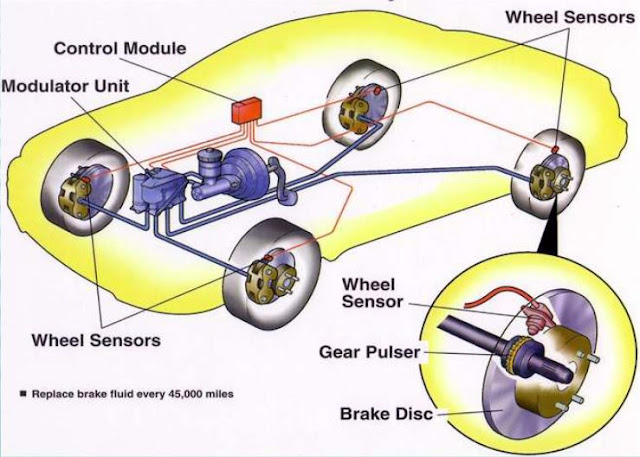

Main components of the Anti-lock Braking System (ABS):

- Wheel speed sensors

- ABS control module or Controller

- ABS modulator and Valves

- ABS Pumps

Wheel Speed Sensors

Wheel Speed Sensors are generally available one on each wheel or in some cases they are located on the differential. It detects a change in acceleration of the vehicle in the longitudinal direction and gives the output signal to the ABS control module.

ABS Control Module or Controller

The ABS control module is a microprocessor that is used to monitor the vehicle’s antilock braking system and processes information from wheel-speed sensors and the hydraulic brake system. When a wheel loses its traction with the ground, a signal is sent to the controller, then the controller limits the brake force (EBD) and activates the ABS modulator to apply braking pressure in a wheel that is about to lock up and start skidding by actuating braking valves with suitable varying pressures.

ABS Modulator and Valves

In some ABS systems, they have separate valves for each wheel with a modulator to control them. In other systems, they are combined. In either case, they work with the controller and the pump to add or release pressure from the individual wheels brakes to control the braking.

Position One – The valve is open and the pressure from the brake's master cylinder directly passes to the brake.

Position Two – The valve is closed, blocks the brake line and isolates the brake from the master cylinder. This prevents the further rise of pressure when the driver applies brake harder on the brake pedal.

Position Three – The valve is in a partially open position and releases some of the pressure from the brake.

ABS Pumps

Since the ABS modulator/valves can release pressure from the individual wheels brakes, the system needs some way to restore the pressure when required. That is what the ABS pump does. The signals from the wheel speed sensors are processed by the ABS Control Module and when a wheel slip is detected, the module will give the signal to the valve to release the pressure to avoid the wheel slip. So, the pump is used to restore this pressure lost in ABS. The ABS controller is used to modulate the pressure at the desired level to avoid slipping.

Working of Anti-lock Braking System (ABS)

An ABS system monitors the speed of four wheels by speed sensors to evaluate wheel slippage. Slip can be determined by calculating the ratio of wheel speed to vehicle speed, which is continuously calculated from the four individual wheels when the vehicle is in motion and send to the control module to take appropriate action. During a braking event, the function of the control module is to maintain maximum possible wheel grip on the road without wheel locking by adjusting the hydraulic fluid pressure to each brake by using electronically controlled solenoid valves.Advantages of Anti-lock Braking System (ABS):

- Safe and effective.

- A vehicle with ABS can be stopped at a lesser distance than a non-ABS vehicle.

- Effective directional stability and steering control.

- The brake fluid pressure can be adjusted automatically at each wheel to maintain optimum brake performance.

- We can stop the vehicle easily on the wet surfaces by using ABS.

- A vehicle with ABS has higher resale and it raises the market value of the vehicle.

- Faster reactions of a vehicle in emergency situations because of the completely electronic & computer-controlled system.

Disadvantages of Anti-lock Braking System (ABS):

- The cost of the vehicle with ABS is high. Also, it consumes more maintenance cost.

- ABS requires regular check-ups and maintenance of sensors, valves, and brake fluid.

- It requires complete overhaul on the damage of a few parts in the system.

Some other automotive safety-related articles:

Automotive Safety systems- Introduction

Electronic Stability Control (ESC) - Simple Explanation

Traction Control System (TCS) - Simple Explanation

Electronic Stability Control (ESC) - Simple Explanation

Traction Control System (TCS) - Simple Explanation

Adaptive Cruise Control (ACC)

Tire (Tyre) Pressure Monitoring System (TPMS) - Simple Explanation

Lane Departure Warning (LDW) - Simple Explanation

Night Vision System (NVS) in Automobiles - Simple Explanation

Tire (Tyre) Pressure Monitoring System (TPMS) - Simple Explanation

Lane Departure Warning (LDW) - Simple Explanation

Night Vision System (NVS) in Automobiles - Simple Explanation

Comments

Post a Comment